This project is to design and build switchgear for use on the debarker. The debarker is a Chinese manufactured machine with a 7.5 kW main debarking motor and a reverseable 3 kW feed motor. We aim to power this device using a 15 kW diesel generator.

After conversations with various electrical consultants, a design has been created, using 2 DOL starters with 240 V coils and 4 emergency stop pushbuttons. This design needs to be run past an electrician before parts are ordered.

Next actions:

I just arranged for and had a meeting with an electrician. They told me that the design was correct, and offered to get me a quote. I sent an email off to try to discover the size of the 3 phase outlet which we have on the generator, so now I'm just waiting for those 2 replies.

Next actions:

Some of the equipment will be sourced through the electrician, the rest I've bought myself. Apparently we have a 20 A outlet on the generator, so I also ordered an appropriate male connector.

Next actions:

The 4 E-stops arrived today. I also bought a AC voltage tester so that I can be a bit safer when I do the actual installation.

OK, all the parts have arrived now. Now I need to actually build the design. The first step will be to work out exactly what I already own in the way of 3 phase cable, and then make a plan based on the lengths. All of the terminations are screw lugs, so I won't have any problem with that. I'll take my calipers and a tape measure to the farm, or maybe just bring the cable back here. I think I should try to leave it out there to save trips.

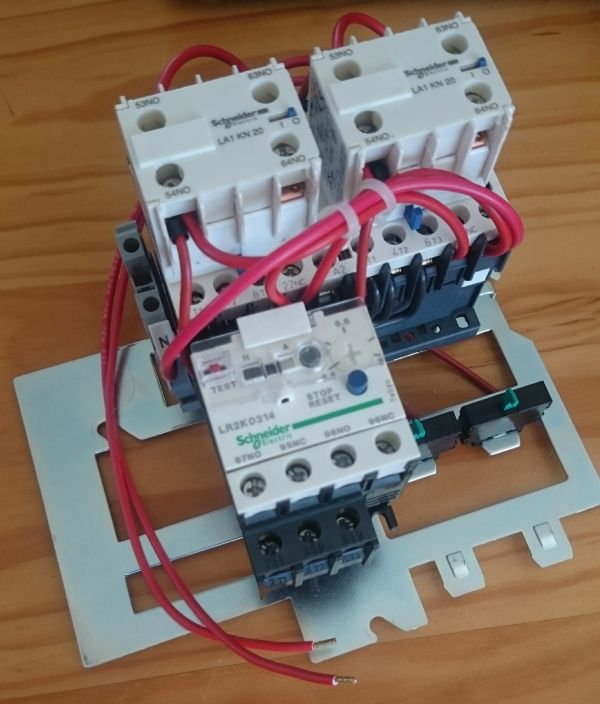

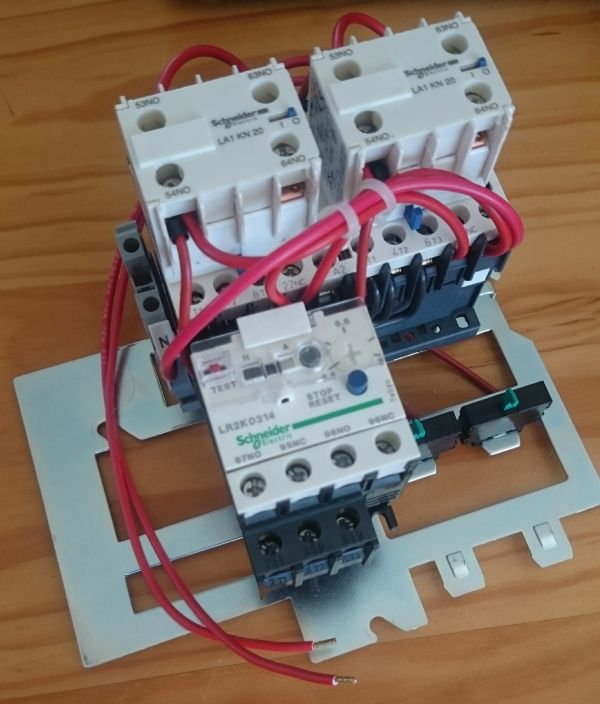

I can't believe it took me this long to check the products! The emergency stop switches work fine. I'm pretty convinced about the DOL 7.5 kW module too. But the 5.5 kW reversing starter is missing the thermal overload protection. I'm going to have to call an electrician tomorrow to see if this is OK. Otherwise, I think this is the right product.

Next actions:

The electrician told me that Rexel is the way to go.

Next actions:

I bought the overload relay. After (probably too much) perusal of the documentation, I think that I understand how to hook these devices up. The main notes:

So, I'll need single phase for connecting the emergency stops, 3 phase to connect the 2 switch boxes, then 3 phase to connect from the generator (through the 20 A outlet) to the switchboxes, and 3 phase to connect from each switchbox to the corresponding motor.

Next actions:

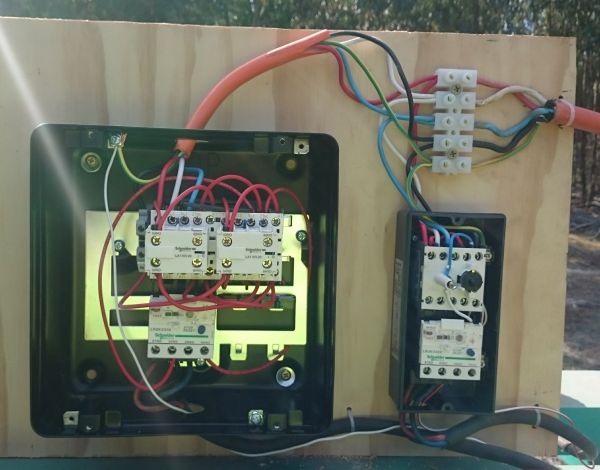

I finally managed to get a hold of the electrician to check the wiring, and he quickly found the problem. When I took it out to the farm and plugged it all in, it worked without a hitch. The generator didn't feel the load of the feed roller, but it certains struggles with the starting of the main rotor, which seems to short the generator for around a second, then hold at 10 A for around 2 more seconds, and then settles at around 6 A. So, now I need to mount all the switchgear on a plywood board as part of a proof of concept, complete with an emergency stop button.

It feels so great to have made some progress on this! What a sense of accomplishment. I'll include some video of the debarker working when the prototype control board has been assembled.

The scope of the switchgear might be increased just slightly to include an hour meter. It only cost $6, so there's nothing to lose. I'll put it just downstream of the starter for the main rotor.

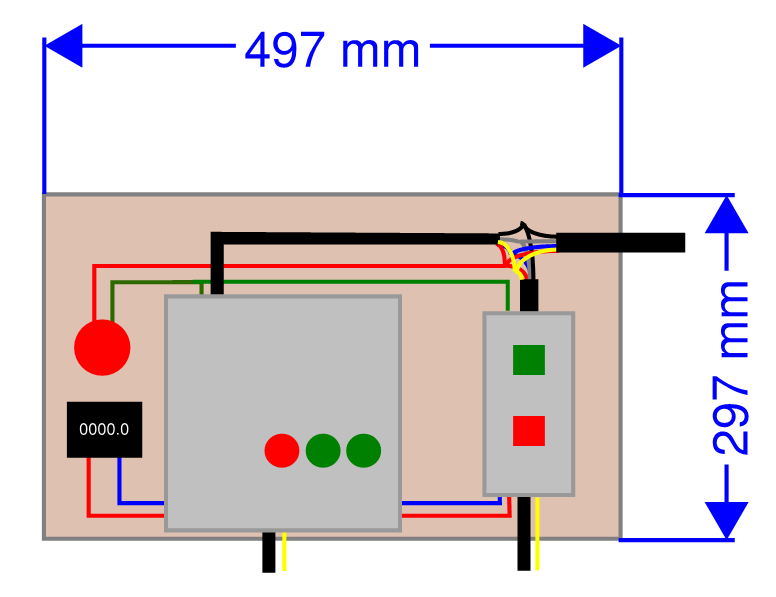

I've started work on the diagram of the switchboard prototype, but it's missing dimensions which I'll add in tomorrow.

Next actions:

I finished my sketch:

Next actions:

The debarker was tested today with 2 trees, and it performed well. I mounted the electronics on site, and they worked flawlessly.

Next actions:

Finally got around to testing my calculations for the sizing of the earths for the motors. Using P = 25 KVA, X" = 0.15 Ohm, PF = 0.8, and V = 415, FLA = 25/(sqrt(3)*V) = 35 A, and then FC = FLA/X" = 232 A. For a 0.1 second connected load, the area of the cross-section should be 0.54 mm^2, and my current wiring is 0.4 mm^2. But protection will probably (I need to check the breaker to be sure) kick in sooner than 0.1 s, so I think that what I've done is fine. Just documenting my working for future reference.

Next actions: